Galvanized pipe, also known as galvanized steel pipe, is a pipe product that is coated with a layer of metallic zinc on the surface of ordinary steel pipes. The main purpose of galvanized pipe is to prevent corrosion and rust, thereby extending the service life of the steel pipe. Galvanized pipes are divided into two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thicker, uniform coating and strong adhesion, while electro-galvanizing has a lower cost and a smoother surface.

Product Parameters

|

Product name |

High Quality square pipe iron rectangular tube welded Galvanized Square Steel Pipes |

|

Material |

Gr.A, Gr.B, Gr.C,S275J0H,S355JR,S355J0H,S355J2H,A36,SS400,Q195,Q235,Q345 |

|

Surface treatment |

galvanized |

|

Shape |

square or rectangular |

|

Thickness |

0.5-60mm |

|

Length |

1-12M Or customized |

|

OD(outer diameter) |

square 10*10-1000*1000mm rectangular:10*15 800*1100mm Round:10.3mm-609mm Or customized |

|

Technology |

ERW |

|

Usage |

Civil engineering, architecture, steel towers, shipyard, scaffoldings, struts, piles for suppression of landslide and other structures |

|

Certification |

CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,ASTMA500,ASTM A501,AS1163,JIS G3466 |

|

Delivery Time |

7-30 Days |

|

Shipment |

by bulk or load into 20ft / 40ft containers |

|

Packing |

Export standard package, suit for all kinds of transport, or as required. |

|

Payment method |

TT/LC |

Product Specifications

|

Type |

Specifications (mm) |

Thickness (mm) |

|

Square tube |

10*10-15*15 |

0.24-0.31 |

|

17*17-50*50 |

0.24-0.31 |

|

|

17*17-50*50 |

0.33-0.38 |

|

|

17*17-50*50 |

0.40-2.0 |

|

|

17*17-50*50 |

0.24-0.31 |

|

|

17*17-50*50 |

0.33-0.38 |

|

|

17*17-50*50 |

0.40-2.0 |

|

|

60*60-250*250 |

0.5-3.0 |

|

|

Rectangular Pipe |

10*20-75*45 |

0.24-0.31 |

|

10*20-75*45 |

0.33-0.38 |

|

|

10*20-75*45 |

0.40-2.0 |

|

|

10*20-75*45 |

0.24-0.31 |

|

|

10*20-75*45 |

0.33-0.38 |

|

|

10*20-75*45 |

0.40-2.0 |

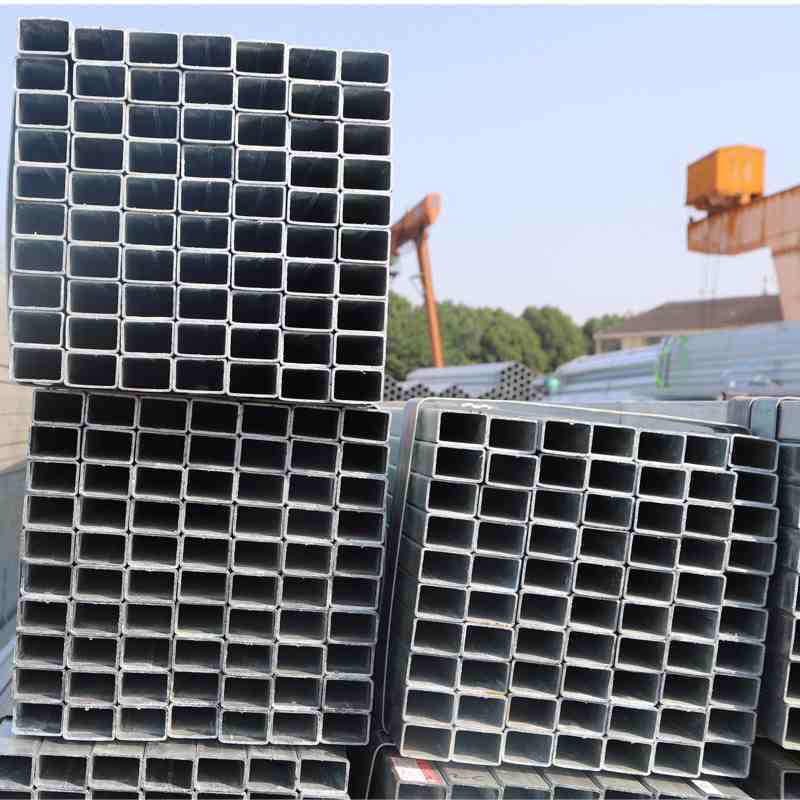

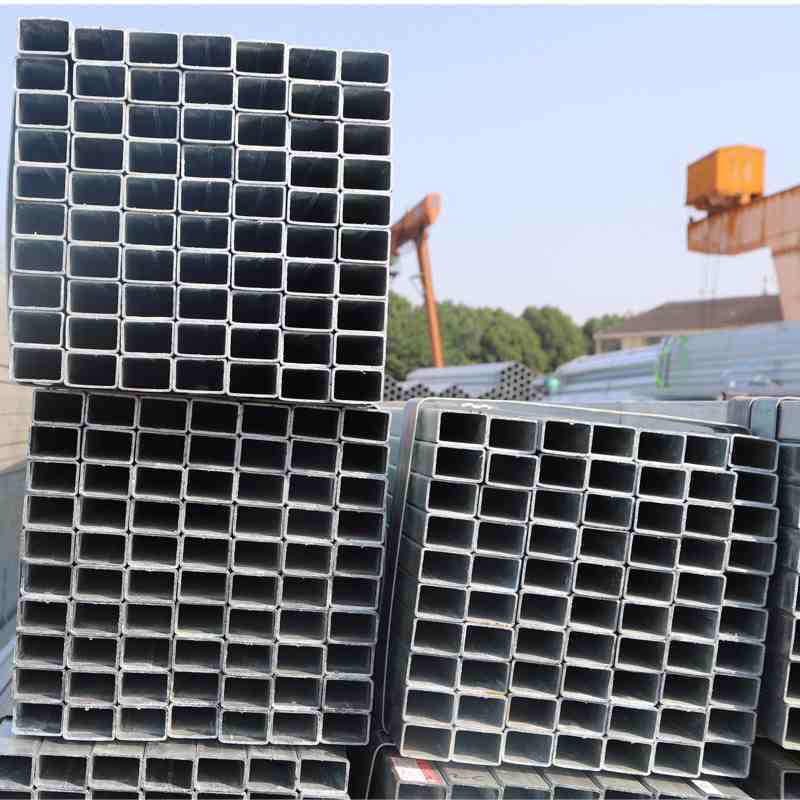

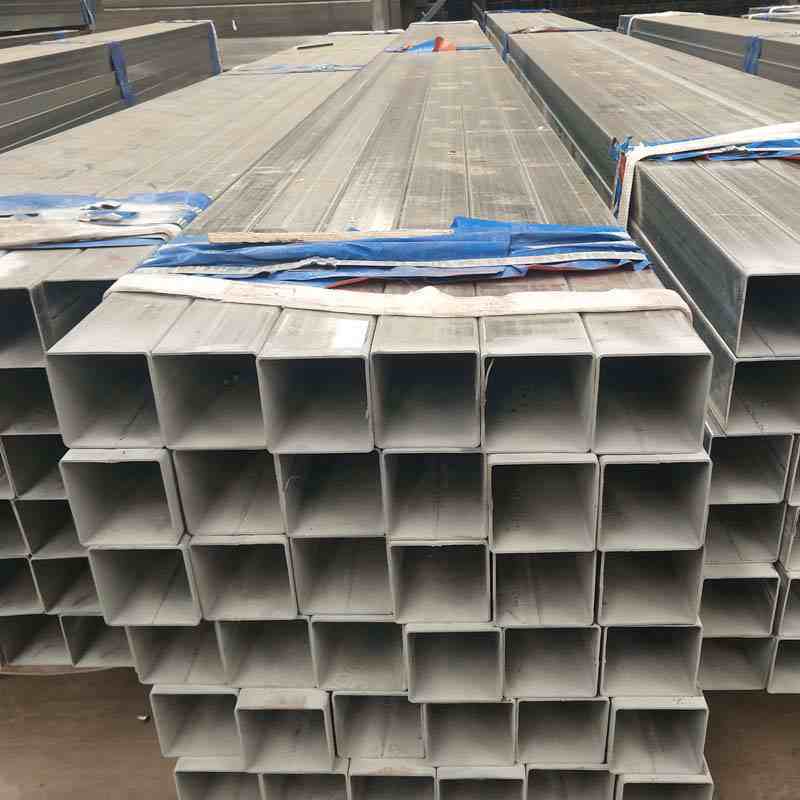

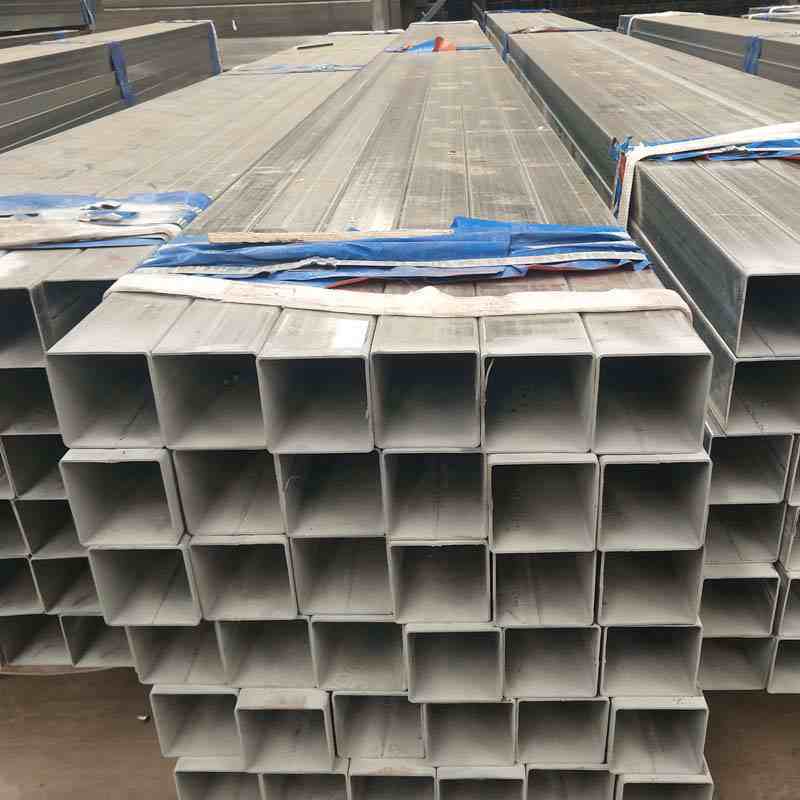

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

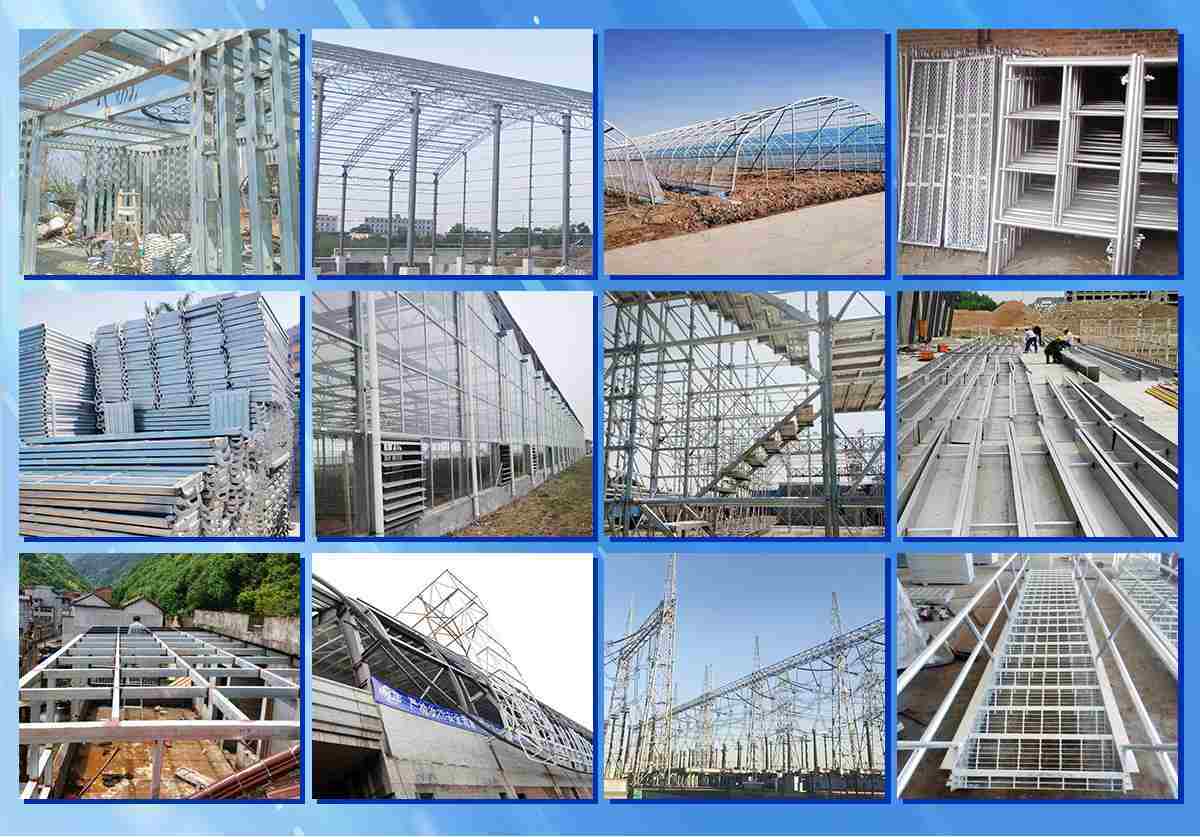

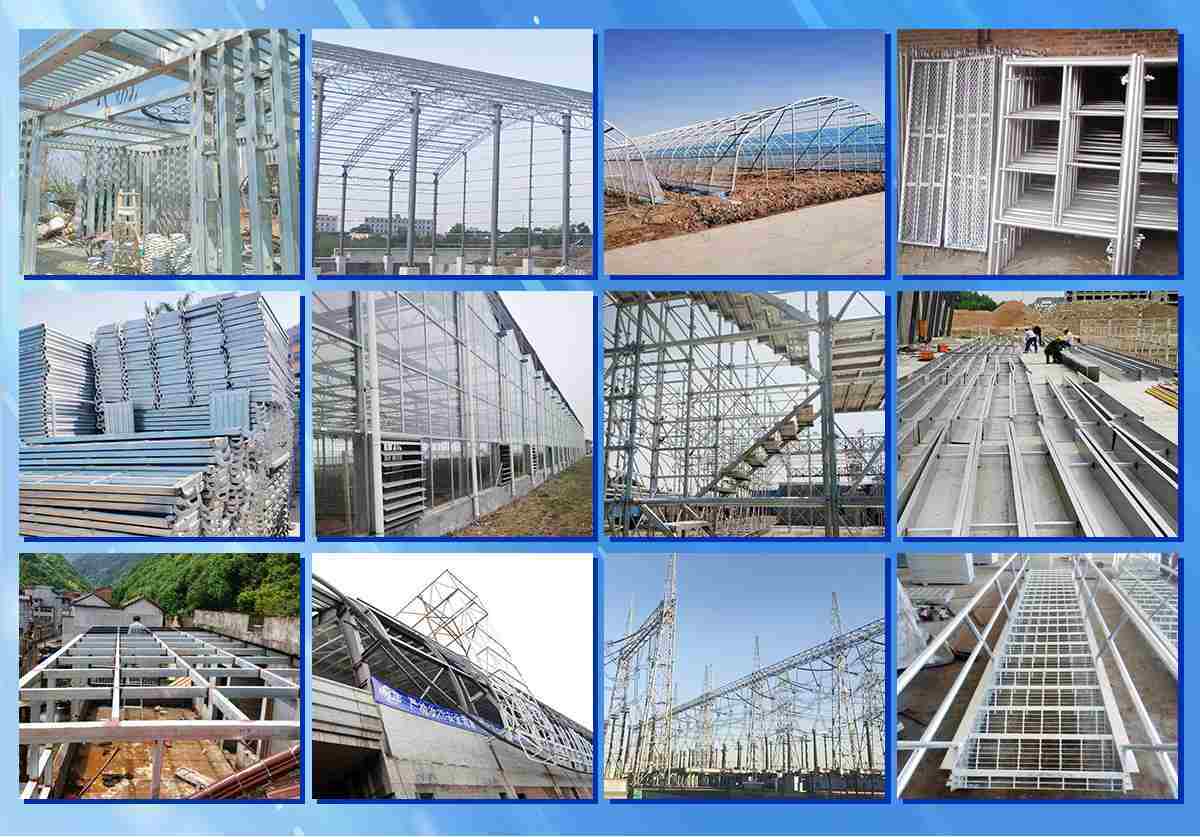

Hot dip galvanized steel pipes are widely used in manufacturing industries such as construction, machinery, coal mines, chemicals, electricity, railway vehicles, automotive industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, exploration machinery, and greenhouse construction.

Project Cases

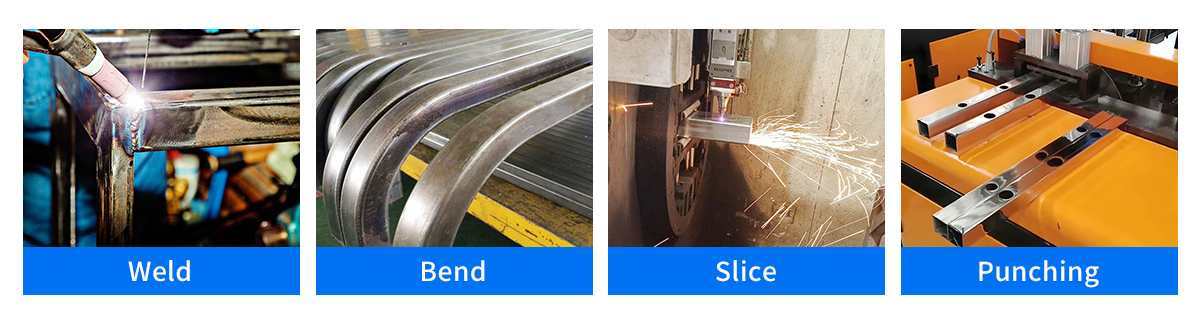

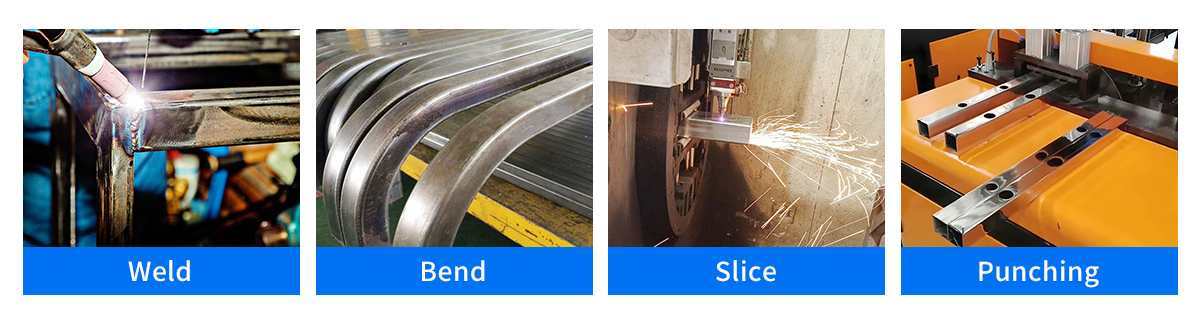

Additional Processing Technology

We can provide additional treatment processes such as cutting, marking, spraying, welding, bending, punching, and surface treatment for galvanized steel pipe.

Product Packaging

Product Transportation